Laney students using 3D printers to create prototypes of their latest inventions in the FabLab may not realize they are part of a global “maker” movement or know about the challenges the project faced before opening in 2015. Danny Beesley, FabLab founder and chief visionary, recalls those early struggles well and is very much aware of the broader social trends that served as his inspiration.

Laney students using 3D printers to create prototypes of their latest inventions in the FabLab may not realize they are part of a global “maker” movement or know about the challenges the project faced before opening in 2015. Danny Beesley, FabLab founder and chief visionary, recalls those early struggles well and is very much aware of the broader social trends that served as his inspiration.

In an exclusive Zoom interview with The Citizen, Beesley said the FabLab (short for “fabrication laboratory”) movement began at the Massachusetts Institute of Technology (MIT) in 2001. MIT professor Neil Gershenfeld, the founder of that first FabLab, was inspired by the vision that “ordinary people will design and build the most extraordinary things if given the right tools.” According to a September 2019 GreenBiz article, the MIT facility launched “an open-source network of makerspaces spread across the globe, doubling in size about every 18 months. As of 2018, there were over 1,300 Fab Labs worldwide.”

Beesley’s “short and sweet” description of the FabLab is “the high tech shop class.” He proudly observes that “within an hour, [students] are given authority to use a $30,000 piece of equipment.”

Earlier in his career, Beesley worked for a firm that built prefabricated homes using computer numeric control (CNC) robotic systems. This technology was widely used in Europe, Beesley said, but was just gaining adoption in the US. “I noticed a major gap,” Beesley said, “and realized we needed a much larger focus on using robotics and automation for construction and especially for training and education.”

When Beesley first approached Laney College about opening a FabLab in 2010, he encountered some resistance. He envisioned the facility being open to students from all departments and majors, rather than being limited to a specific area of study. He also wanted the college to cover the cost of all materials so there would be no cost to the students using the facility.

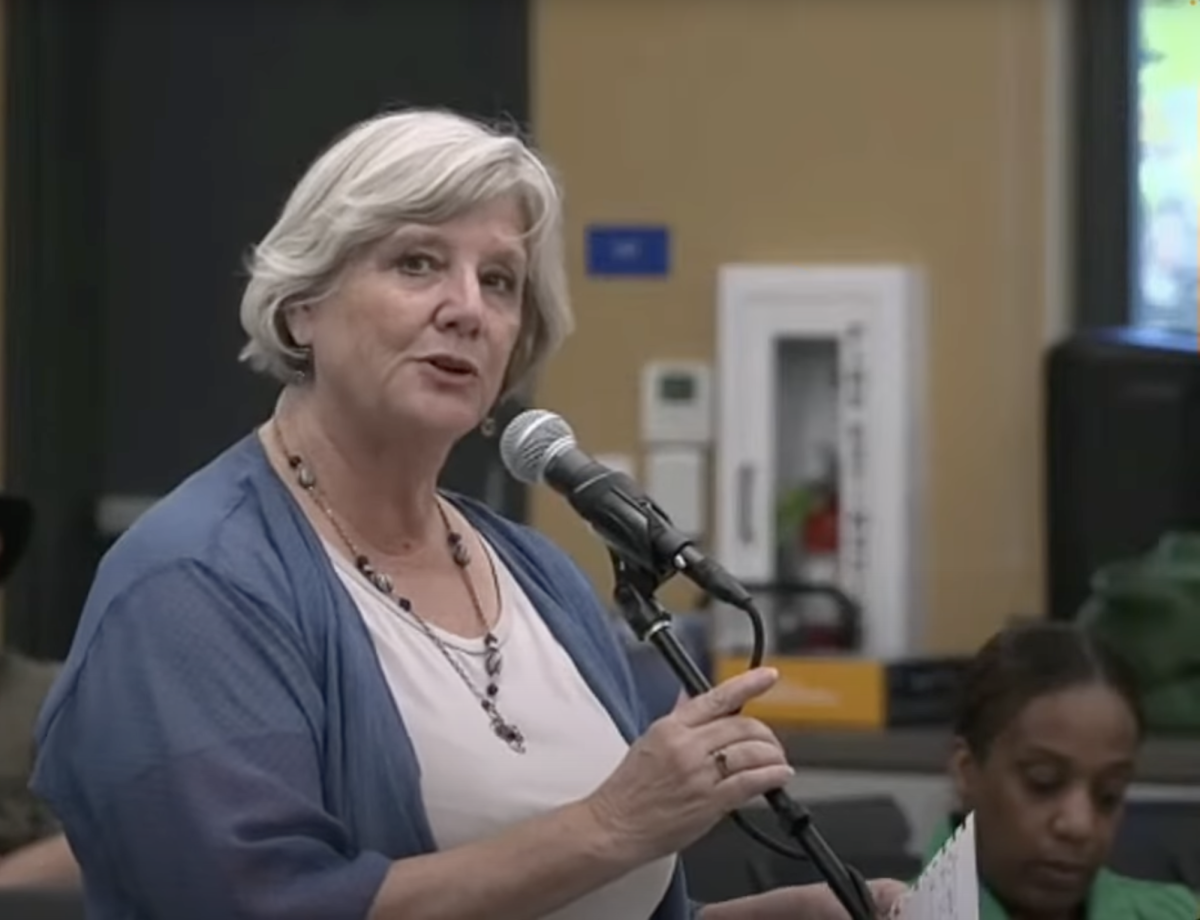

Beesley found an advocate in Professor Cynthia Correia of the Laney carpentry department. “It was primarily with her kind of institutional political support that we were able to get the FabLab built and off the ground,” recalled Beesley. Correia, who was the chair of the Laney carpentry department for 25 years, retired last year.

Beesley also provided Laney with a “proof of concept” by building a FabLab at nearby Castlemont High School in Oakland. “I went off and basically built that facility almost from scratch by myself,” Beesley said. “And I donated the vast majority of my time because I wanted to ensure that the money they were investing [went into the facility] rather than in my pocket.” This demonstrated to the Laney administration that the FabLab concept actually worked.

After five years of lobbying, the Laney FabLab finally opened in 2015. As reported in The Laney Tower (previous name for The Citizen) in October 2014 “the carpentry, wood technology, theater, architecture, and machine technology departments have been working together to fund a ‘Fab Lab’ here on campus that would be open to all students, especially those pursuing education in the STEM fields.” Laney identified 900 square feet adjacent to the carpentry construction area for the first FabLab, according to a description on the fablabs.io site. The space previously served as a loading dock for the theater department.

Since then, hundreds of projects have passed through the FabLab and a second facility was opened at College of Alameda in 2018.

The FabLabs have remained open since Peralta shifted to online instruction in March, but students now submit their designs to the FabLab crew rather than coming in and operating the equipment themselves.

The FabLabs have also used their equipment and know-how to manufacture face shields for local healthcare workers and masks for the general public, as reported in an award-winning Citizen article from April 20.

Other notable inventions from the FabLab include a line of gourmet chocolates developed by Laney student Leah Vass and a line of high-end speakers for use at concerts and events, designed by Ulan McKnight. Laney alum Jimmy Krehl even met his future wife in the FabLab.

When asked which student’s FabLab invention most stands out in his mind, Beesley recalls an iPad cover shaped like a retro TV. Based on Beesley’s encouragement, the student opened an Etsy account and “within 48 hours, he had customers,” Beesley recalled.

Beesley’s goal is to expand use of the FabLab beyond the disciplines most likely to use it. “You don’t have to have a background in design, construction, or carpentry in order to get value out of it,” he explained. One example is the creation of three dimensional topographic maps by geography students.

The FabLab at College of Alameda has a stronger focus on apparel design, in line with that college’s career and technical education (CTE) curriculum. Beesley pointed out that the College of Alameda FabLab also supports the aviation, art and biology departments.

With all the good the FabLabs bring to the district, funding still continues to be a challenge for the Peralta FabLab facilities.

“When the budget crunch comes, all the non-essential things are cut first,” Beesley said. Because the Peralta FabLabs are not “specific to a program,” Beesley is concerned the district may see them as “essentially non-essential.” While Laney extended the contracts for two FabLab staff members through the end of the school year, Beesley said his own contract has not yet been renewed. By contrast, College of Alameda still provides him with financial support. Despite the budget challenges, the FabLab has remained true to its original goal of providing all materials free of charge to students.

Beesley believes the future of the FabLab movement lies in a new initiative called FabCities. The program began in Barcelona in 2014, he explained, “with the audacious goal of producing 50% of everything that is consumed within the city limits by 2054.” In 2018, Beesley and other FabCity proponents successfully lobbied Oakland mayor Libby Schaaf to endorse the program, although it is still awaiting approval from the city council.